Industrial Radial Arm Saw for Wood Packaging – TopShelf Wood Packaging

TopShelf Wood Packaging manufactures wooden pallets, crates, boxes, dunnage, and other specialty wood shipping products.

Need Help? 800-733-4063

These high-quality tools and systems make your work easier and production more efficient. We offer solutions tailored to your cutting needs, including Dust Shrouds for a cleaner workspace, Rip Conversion Kits for versatile cuts, and advanced options like Mist Coolant Systems, Pneumatic Clamping Systems, and Electronic Powered Crossfeed Systems. Each accessory is built for durability and performance, making your saw more versatile and your work more efficient. Explore our selection to find the perfect addition to your equipment.

Showing 1–12 of 38 resultsSorted by price: high to low

POPULAR

New Lower Price

New Lower Price

POPULAR

New Lower Price

The Dust Shroud connects to the back of the frame behind the saw blade and collects dust when the saw makes straight and bevel cuts. In fact, this dust shroud has a 4″ dust port connection for easy attachment to many dust collection systems. During cutting, a laser cut grid covers the port and prevents large pieces of debris from entering the dust collection system.

All wood cutting radial arm saws and beam saws can be equipped with a Dust Shroud. On a radial arm saw, the dust shroud mounts at the rear of the frame and behind the blade. Beam saw dust shrouds mount inside the frame.

The Rip Conversion Kit contains attachments and guarding to allow 12”, 14” and 16” wood cutting saw models to rip cut. First, the motor swivels parallel with the fence. Next, it enables wide boards to be cut in narrower pieces.

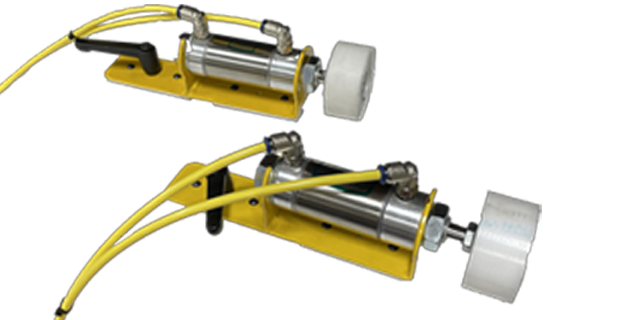

Metal Cutting Radial Arm Saw and beam saws use Mist Coolant Systems. They provide lubrication when cutting non-ferrous material like aluminum and, most importantly, extend the life of the blade. Consequently, if a Mist Coolant System isn’t used, aluminum will fill the gullets of the blade and cause inefficient cutting.

The Mist Coolant System works with a siphon delivery system. It contains a 7” flexible plastic nozzle, sight gauge and independent air and coolant controls for a variable spray delivery. Additionally, compressed air and 110 volt power are required for use .

Pneumatic clamps hold the Mist Coolant System in place in order to it make easy to attach or remove the system. Mist Coolant Systems are an optional feature on all Metal Cutting Super Duty Series Saws and Beam Saws.

Pneumatic clamping creates opportunities to make your cutting more efficient. Two or four cylinder systems allow you to customize how you want to hold the material down. Original Saw’s Pneumatic Clamping System is a wood and metal cutting accessory.

It integrates with our Heavy Duty Series, Super Duty Wood Cutting Series, Super Duty Metal Cutting Series and Beam Saws to allow for a variety of cutting and clamping options.

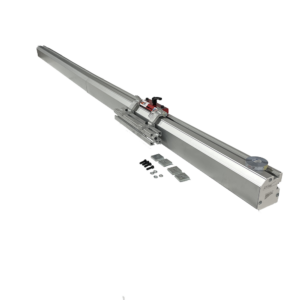

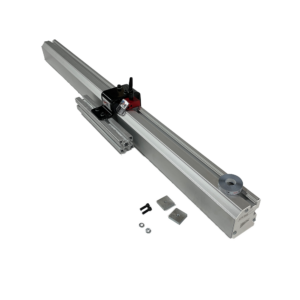

When using a manual saw, the user pulls the carriage through the material that is being cut. When a semi-automatic saw is ordered from our factory, an Electronic Powered Cross Feed option is added to the saw. If the saw is semi-automatic, the carriage is controlled by the push of a button. The remote mounted control panel contains an arbor motor start/stop station, e-stop, carriage forward and reverse buttons, variable speed adjustments and an on/off lighted selector switch. This video shows a Beam Saw with an Electronic Powered Cross Feed and a remote mounted control panel.

Yes! The length of cut or carriage travel is adjusted by the cam stops. The Electronic Powered Cross Feed provides the optimum feed rate for the material to be cut. Most importantly, it assures uniform cuts and maximum utilization of the blade for efficient cutting.

This Electronic Powered Cross Feed is only available at the time of purchase of a Radial Arm Saw. Contact customer service for assistance when choosing an Electronic Powered Cross Feed.

Highlighting effective strategies from our clients.

TopShelf Wood Packaging manufactures wooden pallets, crates, boxes, dunnage, and other specialty wood shipping products.

Black Bros. Co. is a family-owned, sixth-generation roll coating and laminating equipment manufacturer established in 1882.

Leverette’s Construction has been in business for over 20 years. They specialize in general contracting and providing high-quality construction services to their customers.

Safety Speed, a leader in panel processing and fabricating equipment, needed an upgraded cutting solution for their packaging department.

Charlie Kulisan, the owner of Kulisan Woodworking, is an advanced hobbyist woodworker. When searching for a replacement saw to handle crosscuts and dadoes, he prioritized safety and durability.

Central Florida Lumber, a family-owned leader in commercial building materials, specializes in doors, hardware, and millwork. The company needed a more efficient method to cut custom doors for its steel door customers.

Ask about sending in a material sample to Original Saw. We will cut your material on our shop saw and make a video. Afterwards, you can review the videoed test cuts and make informed decisions. Most importantly, we want you to feel comfortable with your solutions before your purchase.

Email us at customerservice@originalsaw.com or call at (800) 733-4063 to start the process.

If Saw Extension Tables are purchased at the same time as a saw, the tables will be shipped with the saw via freight truck. Lead time on saws with Saw Extension Tables is generally 3-4 weeks.

Saw Extension Tables can also be ordered without a saw. Tables are an in stock item and can be shipped out approximately 2-3 days after the order is placed.

They can be shipped by UPS or by freight truck, depending on the size and number of tables ordered. Contact Original Saw Company at (800) 733-4063 or customerservice@originalsaw.com for a freight quote.

Use the diagrams below to identify the type and year of your saw. This will help us find your needed part.

When determining the replacement parts needed for a radial arm saw, it is important to know the series and serial number of the saw. The serial number is located on a riveted tag on the front of the frame on a radial arm saw. Beginning in 1995, Original Saw Company assigned serial numbers by year, month, series and numerical.

A manual is sent with each radial arm saw. It provides important safety information, diagrams and instructions. Refer to the manual to determine the parts needed.

Can’t find your manual?

When determining the replacement parts needed for a beam saw, it is important to know the series and serial number of the saw. The serial number is located on a riveted tag on the front of the frame on a beam saw. Beginning in 1995, Original Saw Company assigned serial numbers by year, month, series and numerical.

A manual is sent with each radial arm saw. It provides important safety information, diagrams and instructions. Refer to the manual to determine the parts needed.

Can’t find your manual?

When determining the replacement parts needed for a Crosscut saw, it is important to know the series and serial number of the saw. The serial number is located on a riveted tag on the front of the frame on a crosscut arm saw. Beginning in 1995, Original Saw Company assigned serial numbers by year, month, series and numerical.

A manual is sent with each crosscut saw. It provides important safety information, diagrams and instructions. Refer to the manual to determine the parts needed.

Can’t find your manual?

Have questions or need assistance in selecting the right saw?

Our experts are here to help you choose the right equipment and systems for you.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_N787K37DYQ | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_9586239_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| Cookie | Duration | Description |

|---|---|---|

| GetLocalTimeZone | session | No description |

| woocommerce_recently_viewed | session | Description unavailable. |

| wp_woocommerce_session_f5cd7dc109f1c0b99afb63cf04893d56 | 2 days | No description |

Select at least 2 products

to compare