Central Florida Lumber

Central Florida Lumber, a family-owned leader in commercial building materials, specializes in doors, hardware, and millwork. The company needed a more efficient method to cut custom doors for its steel door customers.

Need Help? 800-733-4063

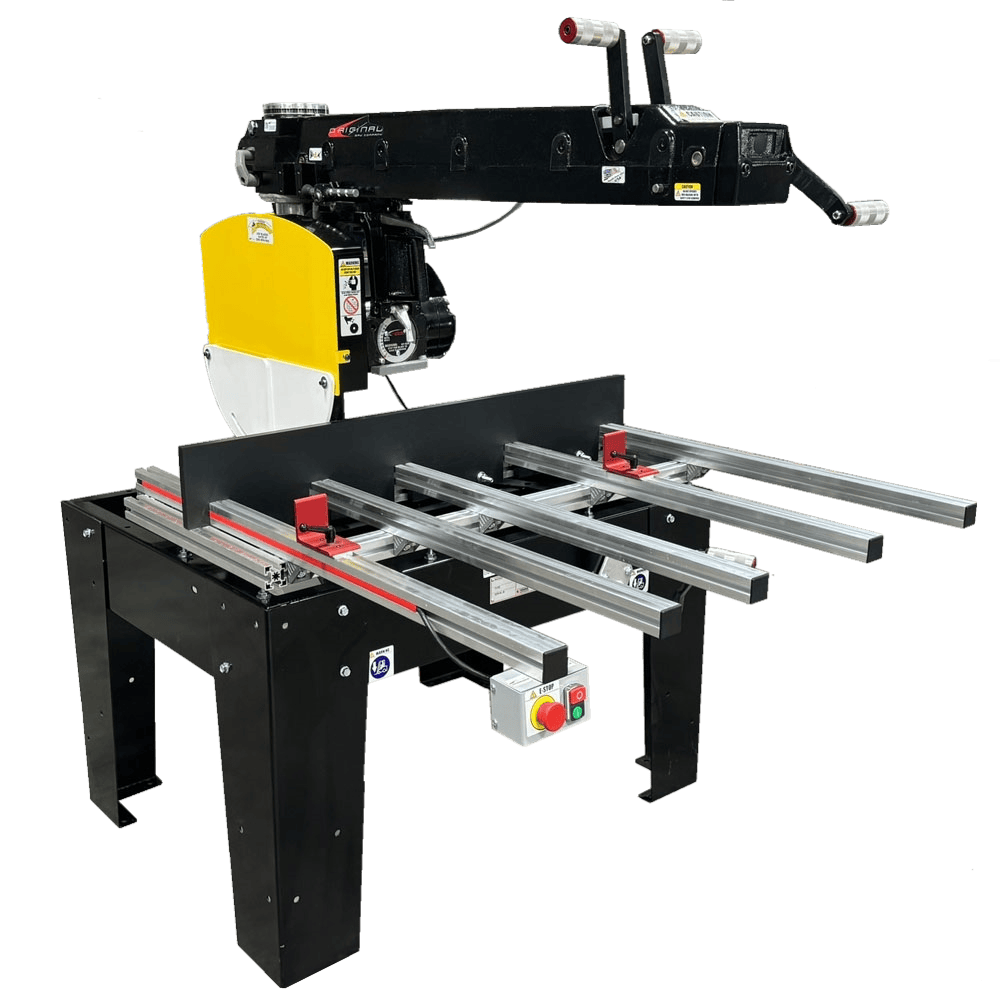

Original Saw Company’s Metal Cutting Radial Arm Saws set the standard for durability, precision, and versatility in industrial cutting. Proudly manufactured in our Northern Iowa facility, these American-made machines handle the most challenging materials, including steel, aluminum, brass, plastics, and fiberglass, with exceptional accuracy and reliability.

Built with cast and ductile iron construction, these 900+ pound machines provide a vibration-free cutting platform for consistent results. Our saws have advanced safety features, powerful motors, and customizable options, which meet the demands of high-volume industrial environments.

Whether performing straight cuts or complex bevel and miter cuts, these Radial Arm Saws deliver unmatched performance across industries like metal fabrication, aerospace, construction, and more. Experience the craftsmanship and innovation of Original Saw Company’s Metal Cutting Radial Arm Saws—built to last and proudly made in the USA.

Showing all 3 resultsSorted by price: high to low

POPULAR

Original Saw Company’s Metal Cutting Radial Arm Saws set the benchmark for precision, durability, and safety when cutting metals. Proudly manufactured in the USA, these saws feature in-house built motors, heavy-duty cast iron construction, and UL-certified custom electrical panels.

Designed with advanced features like fully enclosed blade guards, Variable Frequency Drives (VFD), and emergency stop functionality, these machines offer unparalleled reliability and operator protection. Supported by U.S.-based customer service, our Metal Cutting Radial Arm Saws withstand the demands of industrial environments, providing a trusted cutting solution for generations.

At Original Saw Company, we manufacture high-quality motors in-house to ensure superior performance and reliability for our machinery. We design our motors for durability and to withstand continuous use in demanding industrial environments. This in-house production allows us to maintain strict quality control and tailor the motors to the specific needs of our machines.

Each motor is equipped with our totally enclosed, fan-cooled (TEFC) technology, which protects it from dust and debris, improves durability, and reduces maintenance needs.

Original Saw Company’s Metal Cutting Radial Arm Saws are engineered with rugged, industrial-grade materials to withstand continuous use in industrial environments. We construct our saws from high-quality cast iron and aluminum to provide a vibration-free cutting platform. This rigidity allows for consistent performance across various cutting operations.

The solid construction, including powder-coated steel in the legs and frame, provides long-lasting durability and strength. Designed for optimal performance, these machines deliver accurate cuts, and are built to last for generations.

The Metal Cutting Series comes standard with a T-slot extruded aluminum table top. This table allows for easy attachment of our aluminum fence, clamping systems, alternate table surface options, and your own custom clamping jigs or cutting fixtures. The table is mounted to an extruded leveling frame for easy adjustments and to maintain a level surface throughout the machine’s life.

The T-slot design also accommodates manual clamps that slide along the rail, providing secure and flexible workpiece positioning. This upgraded table offers the strength and support needed for heavy-duty cutting operations, making it a reliable feature of the Metal Cutting Series.

The Metal Cutting Radial Arm Saw from Original Saw Company is designed with essential safety features to protect operators during cutting operations. A fully enclosed blade guard covers both the top and bottom of the blade, minimizing exposure and preventing accidents while still allowing clear visibility of the cutting area.

One of the standout features is the exclusive door-style guard, which allows for quick and easy blade changes. This guard should only be opened when changing the blade. The door-style guard makes it an essential feature for ferrous cutting applications where frequent blade changes are required to maintain optimal cutting performance and safety. The ability to easily swap blades ensures operators can always use the best blade for the job without compromising on safety.

Heat generation can become an issue when cutting metal, leading to reduced blade life and compromised cut quality. To address this, the Metal Cutting Radial Arm Saw from Original Saw Company has a Mist Coolant System to help manage heat and improve the cutting process.

Mist coolant provides several benefits when used with the saw. It cools both the blade and the material being cut by reducing friction and preventing overheating. This not only prolongs the blade’s life but also results in cleaner, more precise cuts. Additionally, the coolant helps to control the spread of metal particles and chips and keeps the work area cleaner and safer.

The Metal Cutting Radial Arm Saw from Original Saw Company has an Emergency Stop (E-Stop) button. The E-Stop is a critical safety feature designed to halt the saw’s operation in an emergency immediately. Positioned for easy access, operators can quickly stop the saw’s blade to prevent accidents and reduce the risk of injury.

In industrial environments, where metal cutting requires precision and safety, the E-Stop adds an extra layer of control. This feature is essential when working with ferrous materials, as sudden issues with material handling or blade operation can occur. Pressing the E-Stop rapidly disengages the saw’s motor and blade, allowing for safe intervention and adjustments before resuming operation.

All models in the Metal Cutting Radial Arm Saw series feature VFD technology. The VFD provides smooth start-ups, consistent power output, and adjustable blade speeds, making it easy to adapt to different materials and blade sizes. The VFD reduces the blade’s acceleration time by over 8 seconds and provides a controlled, slower start-up, enhancing motor life. It also manages braking times, slowing and stopping the saw in approximately 25 seconds for safe, consistent operation.

At Original Saw Company, we design and build custom electrical panels tailored specifically to our machinery. The in-house panel production provides seamless integration and top-notch performance. Our panels are certified for the North American market, meeting CSA (Canada) and UL508A (United States) standards. With certification from ETL labs, our panel shop guarantees compliance with these rigorous specifications.

One advantage of having an onsite UL-listed panel shop is the enhanced quality control. Our team constructs and thoroughly inspects each panel at our facility, helping maintain high standards while controlling costs. In addition, we can build panels to accommodate various voltages, including those required for overseas markets.

Our standard panels offer reliable machine control. They feature low-voltage operation, over-current thermal protection, and an emergency stop (E-Stop) for added safety.

Customized panel solutions allow us to incorporate additional features like hour meters to track arbor motor run time. By building our panels, we can offer tailored solutions for adjusting blade speed to suit different materials or accommodate larger blade sizes.

Metal Cutting Radial Arm Saws share several key features across all models, making them perfect for demanding industrial use. These versatile machines perform a variety of cuts, including bevel, compound miter, crosscuts, and miter cuts. However, they aren’t designed for rip cuts.

Built in the USA, these saws excel at cutting aluminum, steel, brass, and fiberglass. They come equipped with essential safety features like an E-Stop and offer various voltage options to suit different needs. All models have similar weights and shipping dimensions.

Designed for heavy-duty use, these saws can handle 2-3 shifts daily, providing reliable and continuous operation for industrial environments.

16" Metal Cutting Radial Arm Saw |

20" Metal Cutting Radial Arm Saw |

POPULAR 22.5" Metal Cutting Radial Arm Saw |

||

| SKU | 3579-16 | 3579-20 | 3579-22 | |

| Weight | 1000 lbs | 1100 lbs | 1100 lbs | |

| Dimensions | 72 × 52 × 48 in | 72 × 52 × 48 in | 72 × 52 × 48 in | |

| Price | $12,528.30 – $13,252.21 | $12,861.48 – $13,480.99 | $14,321.03 – $15,107.14 | |

| Motor | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor, 7.5 hp 3 phase TEFC (totally enclosed fan cooled) motor, VFD control with single phase input | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor | |

| Capable of Rip Cuts | No | No | No | |

| Made in USA | Yes | Yes | Yes | |

| Max Depth Cut | 5" deep | 7" deep | 8" deep | |

| Max Crosscut | 24” wide, 32” wide | 26 1/2” wide, 24” wide | 17 3/4” wide, 25 3/4” wide | |

| Product Width | 48" wide | 48" wide | 48" wide | |

| Voltage Options | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | |

| Cuttable Material | Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel | Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel | Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel | |

| Product Height | 68" high | 70" high | 71" high | |

| Recommended Usage | Capable of running 2-3 shifts per day | Capable of running 2-3 shifts per day | Capable of running 2-3 shifts per day | |

| Can do the following cuts | Bevel, Compound Miter, Crosscut, Miter | Bevel, Compound Miter, Crosscut, Miter | Bevel, Compound Miter, Crosscut, Miter | |

| Phases of Voltage Available | 3 Phase, Single Phase | 3 Phase | 3 Phase | |

| Pneumatic Clamping Ability? | Yes (Add on) | Yes (Add on) | Yes (Add on) | |

| Electronic Powered Cross Feed Option? | Yes (Add On) | Yes (Add On) | Yes (Add On) | |

| Motor Phase | Single Phase, 3 Phase | - | - | |

| E-Stop | Yes | Yes | Yes | |

| Max Depth of Cut at 45 Deg Bevel | 2" deep | 3 1/4" deep | 4" deep | |

| Max Crosscut at Max Depth | 20 1/2" wide, 28 1/2" wide | 18 1/2" wide, 26 1/2" wide | 17 3/4” wide, 25 3/4” wide | |

| Product Depth | 58" deep, 66" deep | 58" deep, 66" deep | 58" deep, 66" deep | |

| Max Miter at ¾” | 16" wide, 21 5/8" wide | 14" wide, 18 1/2" wide | 12 1/2" wide, 22" wide | |

| Table Height | 36" high | 36" high | 36" high |

Original Saw Company’s Metal Cutting Radial Arm Saws handle a wide range of industrial cutting tasks with precision and reliability. Capable of cutting through materials such as aluminum, steel, brass, bronze, plastics, and fiberglass, these saws offer unmatched versatility. Beyond straight cuts, some models can perform miter, bevel, and compound miter cuts, making them ideal for various metal fabrication and manufacturing applications.

Built from cast and ductile iron with heavy-gauge steel, these 900-pound machines provide vibration-free operation for precise, consistent cuts. Available in manual and semi-automatic models, Metal Cutting Radial Arm Saws can be customized with optional equipment to boost efficiency and productivity in industrial settings.

Secure material properly using clamps or hold-downs to avoid shifting during cutting. The Metal Cutting Radial Arm Saw has a T-slot extruded aluminum table that allows manual or pneumatic clamping systems to be attached easily. Manual clamping provides a straightforward, reliable way to hold materials in place during cutting, ideal for smaller or less frequent projects.

Pneumatic clamping offers an automated solution for larger or high-volume jobs. It creates consistent pressure and secure material placement for every cut. Both options help keep your material steady to make accurate, safe cuts.

The Metal Cutting Radial Arm Saw comes standard with manual hand crank operation, giving you complete control over the saw’s movement. This allows you to adjust the feed rate based on the material you’re cutting, making it ideal for precise work, such as cutting large timbers, metal cutting applications, and heavy dado work.

You can upgrade to an Electronic Powered Cross Feed for faster, more efficient cuts. This semi-automatic option automates cutting by pushing a button to move the saw through the material and automatically returning it to the starting position. The Electronic Powered Cross Feed is particularly useful for high-volume or repetitive tasks, providing consistent, smooth movement and greater efficiency.

Metal Cutting Radial Arm Saws are widely used in various industries, including metal fabrication, automotive, aerospace, and construction. They are also essential for:

These industries rely on the precision and efficiency of Metal Cutting Radial Arm Saws for their specialized cutting needs.

The Metal Cutting Radial Arm Saw can handle ferrous metals like steel and iron.

For cutting materials up to 8 gauge, use high-speed steel friction-cutting blades, which operate at 3400 RPM. These blades melt through the material, offering speed over cut quality. The cuts are precise, but a slight burr may form due to the friction process. The burr size can vary based on material thickness, carriage speed, and material type. It’s important to note that using mist coolant for ferrous cutting is prohibited, as it can increase the burr size.

The Metal Cutting Radial Arm Saw easily cuts non-ferrous metals like aluminum, copper, and brass. To make clean and precise cuts, choosing the right blade is crucial. For materials with a wall thickness under 1/8″, use a high-speed steel blade with 250-300 teeth. For materials 1/8″ or thicker, opt for a carbide-tipped non-ferrous blade with a negative 5-degree hook. This type prevents the blade from grabbing the material and ensures a smooth finish.

Also, consider the stiffness and shape of the extrusion when choosing a blade. Thin walls with flat areas may flex or chatter during cutting, potentially damaging the carbide teeth. For most non-ferrous cutting applications, we recommend using a Mist Coolant System, which extends blade life and improves cut quality. Material can clog the blade’s gullets without coolant, leading to more frequent sharpening.

We designed the Metal Cutting Radial Arm Saw to cut a variety of metals, including both ferrous (steel, iron) and non-ferrous materials (aluminum, copper, brass). This versatility makes it an excellent choice for different industrial applications.

Highlighting effective strategies from our clients.

Central Florida Lumber, a family-owned leader in commercial building materials, specializes in doors, hardware, and millwork. The company needed a more efficient method to cut custom doors for its steel door customers.

Black Bros. Co. is a family-owned, sixth-generation roll coating and laminating equipment manufacturer established in 1882.

Safety Speed, a leader in panel processing and fabricating equipment, needed an upgraded cutting solution for their packaging department.

Original Saw Company provides various customization options to optimize your Metal Cutting Radial Arm Saw for specific industrial applications. Enhance efficiency and precision with features like Electronic Powered Cross Feed for automated cutting, Pneumatic Clamping Systems for secure material handling, and Mist Coolant Systems to improve blade life and cut quality.

For additional durability and precision, HDPE Black Plastic Table Insert Kits offer a smooth, wear-resistant surface ideal for heavy-duty cutting tasks. These customizations are tailored to meet the specific demands of your operation, delivering reliable and efficient performance for every cutting task.

Upgrade to semi-automatic operation with push-button control for smooth and efficient cutting. The blade automatically moves through the material and returns to the starting position, ideal for repetitive tasks.

These durable inserts provide a stable cutting surface. Ideal for cutting smaller materials, the inserts help maintain workpiece stability and accuracy. They are designed to fit seamlessly into the table’s T-slot system and offer additional support for more detailed cutting tasks.

Improve blade life and cut quality with a mist coolant system, which reduces friction, prevents overheating, and helps maintain a cleaner workspace during non-ferrous material cutting.

Achieve consistent material holding with pneumatic clamping. This system applies uniform pressure, making it ideal for high-volume or precision cutting tasks.

Ask about sending in a material sample to Original Saw. We will cut your material on our shop saw and make a video. Afterwards, you can review the videoed test cuts and make informed decisions. Most importantly, we want you to feel comfortable with your solutions before your purchase.

Email us at customerservice@originalsaw.com or call at (800) 733-4063 to start the process.

Have questions or need assistance in selecting the right saw?

Our experts are here to help you choose the right equipment and systems for you.

Don’t miss out on valuable company updates from us!

"*" indicates required fields

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_N787K37DYQ | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_9586239_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| Cookie | Duration | Description |

|---|---|---|

| GetLocalTimeZone | session | No description |

| woocommerce_recently_viewed | session | Description unavailable. |

| wp_woocommerce_session_f5cd7dc109f1c0b99afb63cf04893d56 | 2 days | No description |

Select at least 2 products

to compare