TopShelf Wood Packaging

TopShelf Wood Packaging manufactures wooden pallets, crates, boxes, dunnage, and other specialty wood shipping products.

Need Help? 800-733-4063

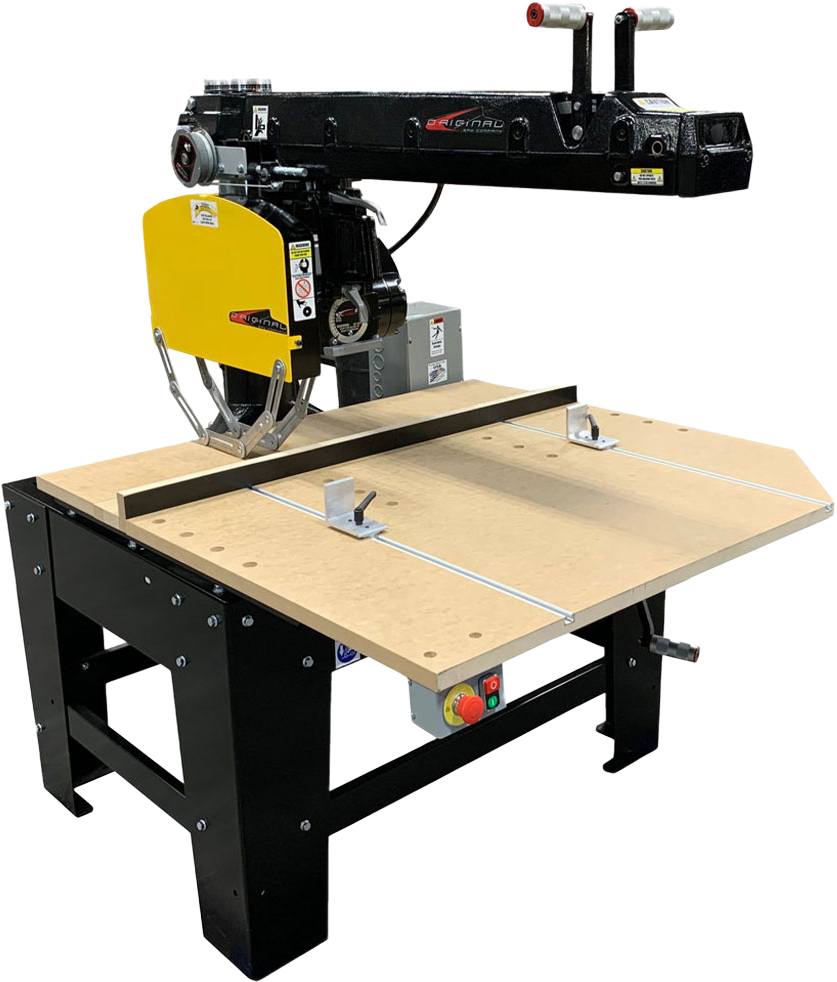

Original Saw Company’s Wood Cutting Radial Arm Saws deliver unmatched precision, durability, and safety, setting the industry standard for woodworking and industrial cutting applications. Proudly manufactured in our Northern Iowa facility, these American-made saws easily cut wood, wood products, plastics, and composite materials.

Engineered for performance, our Radial Arm Saws feature heavy-duty steel frames, precision linear guides, and powerful motors to endure the rigors of daily use. Whether performing crosscuts, dado cuts, or bevel cuts, these versatile saws deliver consistent, repeatable results.

These saws are customaizable with multiple accessores to enhance productivity and meet specific application needs. Professionals in industries such as custom cabinetmaking, vocational education, lumberyards, and manufacturing plants trust our Radial Arm Saws.

Experience the craftsmanship, reliability, and innovation of Original Saw Company’s Radial Arm Saws. Built for demanding environments and proudly made in the USA, these saws are essential for achieving precision and performance in any cutting task.

Showing all 6 resultsSorted by price: high to low

POPULAR

Original Saw Company’s Wood Cutting Radial Arm Saws are the industry standard for precision, durability, and safety. Proudly made in the USA, these saws feature in-house manufactured motors, robust cast construction, and UL-certified custom electrical panels, all designed to for superior performance and reliability.

With innovative safety features like integrated blade guards, E-stops, and return reels, our Radial Arm Saws deliver unmatched consistency and protection in woodworking and industrial applications. Supported by U.S.-based customer service, these saws handle rigorous daily use, providing professionals with a trusted cutting solution for generations.

Original Saw Company manufactures all motors in our Northern Iowa facility to ensure the highest quality and performance. These totally enclosed fan-cooled (TEFC) motors feature cooling ducts that maintain optimal temperatures by moving air through the motor laminations. The enclosed design protects internal components from dust and contamination, extending the motor’s life.

We provide braking systems tailored to each Radial Arm Saw’s design.

Both braking systems enhance safety and reliability, reflecting the high standards we maintain in every motor we produce.

Our Radial Arm Saws are built with iron and aluminum cast components, creating a rigid, vibration-free cutting platform. This durable construction delivers precision, minimizes wear, and provides a stable base for various cutting operations, including crosscuts, dado cuts, and bevel cuts. These robust materials make the saws ideal for professional woodworking and industrial environments.

Original Saw Company designs and builds UL508A and CSA-compliant electrical panels in-house, tailored specifically for North American markets and our machinery. Certified by ETL labs, these panels meet rigorous safety and operational standards while offering a range of custom options. Our panels include essential features like low-voltage controls, overcurrent protection, and E-Stops, with options for automation and hour meters to monitor motor runtime.

By manufacturing panels onsite, we maintain strict quality control, ensuring each panel meets our high standards for reliability and performance. This process also allows us to control costs and provide solutions for various voltage requirements, including those for international markets.

Safety is a core focus in the design of our Radial Arm Saws. Each model features heavy-duty blade guards, accessible E-stops, and return reels that automatically retract the saw head to its starting position. These features minimize operator contact with moving parts, reducing the risk of accidents and enhancing overall safety during operation.

Keep a workspace cleaner and healthier with a Dust Shroud Kit for a Radial Arm Saw. These kits capture dust directly at the source, reducing airborne particles and creating a safer environment for woodworking.

The Dust Shroud Kit offers multiple benefits, including improved visibility during cuts, reduced cleanup time, and enhanced project finish quality. It’s a practical upgrade for woodworkers seeking a more organized and efficient workspace.

Original Saw Company offers a range of optional accessories to enhance the functionality of our Radial Arm Saws. Add features like Saw Measuring Systems for precise, repeatable cuts or Saw Extension Tables for improved material support during cutting operations. For enhanced productivity and safety, consider upgrading to Pneumatic Clamping, which securely holds materials in place with minimal effort.

These customizations allow operators to tailor their saws to specific workflow requirements.

Original Saw Company’s Wood Cutting Radial Arm Saws are proudly manufactured in the USA, showcasing superior craftsmanship and a steadfast commitment to quality. These saws deliver consistent, reliable performance for generations of use.

Professionals in woodworking, cabinetry, and industrial applications trust our Radial Arm Saws for their dependable operation and advanced features. Additionally, all customer service is based in the United States, guaranteeing you receive knowledgeable, responsive support from our dedicated team whenever needed.

Original Saw Company’s Wood Cutting Radial Arm Saws share features that guarantee durability, precision, and safety across all models. These saws include in-house manufactured TEFC motors, cast construction for vibration-free operation, and advanced safety features such as blade guards, E-stops, and return reels. Each saw can make crosscuts, dado cuts, miter cuts, compound miter cuts, and bevel cuts with consistent accuracy.

Designed for professional and industrial applications, Wood Cutting Radial Arm Saws excel at cutting wood, wood products, plastics, and composite materials. While every model provides dependable performance, their specific capabilities, such as crosscut size and motor power, allow users to select the ideal saw for their unique cutting needs.

Explore the comparison table to find the perfect solution for your operation.

12" Contractor Duty Radial Arm Saw |

14" Heavy Duty Radial Arm Saw |

POPULAR 16" Heavy Duty Radial Arm Saw |

16" Super Duty Radial Arm Saw |

20" Super Duty Radial Arm Saw |

22.5" Super Duty Radial Arm Saw |

||

| SKU | 3512 | 3531/3536 | 3541/3546 | 3551/3556/3571/3576 | 3553/3558 | 3554/3559 | |

| Weight | 440 lbs | 580 lbs | 580 lbs | 1000 lbs | 1000 lbs | 1000 lbs | |

| Dimensions | 48 × 40 × 48 in | 52 × 50 × 48 in | 52 × 50 × 48 in | 72 × 52 × 48 in | 72 × 52 × 48 in | 72 × 52 × 48 in | |

| Price | $5,899.87 – $5,986.36 | $8,163.91 – $8,429.85 | $8,291.92 – $8,690.84 | $11,476.59 – $12,130.61 | $12,143.22 – $12,551.02 | $13,397.72 – $14,363.24 | |

| Capable of Rip Cuts | Yes | Yes | Yes | Yes | No | No | |

| Max Crosscut | 21 3/4” wide | 16” wide, 24” wide | 16” wide, 24” wide | 24” wide, 32” wide | 23” wide, 31” wide | 17 3/4” wide, 25 3/4” wide | |

| Max Crosscut at Max Depth | 19" wide | 13" wide, 21" wide | 13" wide, 21" wide | 21" wide, 29" wide | 19" wide | 17 3/4” wide, 25 3/4” wide | |

| Max Depth Cut | 3 1/4" deep | 4" deep | 4 3/4" deep | 4 3/8" deep | 7" deep | 8" deep | |

| Made in USA | Yes | Yes | Yes | Yes | Yes | Yes | |

| Product Width | 35" wide | 45" wide | 45" wide | 49" wide | 49" wide | 48" wide | |

| Voltage Options | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | |

| Cuttable Material | Plastic, Wood | Plastic, Wood | Plastic, Wood | Plastic, Wood | Plastic, Wood | Plastic, Wood | |

| Product Height | 61" high | 64 1/2" high | 64 1/2" high | 68" high | 70" high | 71" high | |

| Recommended Usage | Up to 6 hours per day, depending on the size and type of material | Used up to 8 hours per day | Used up to 8 hours per day | Capable of running 2-3 shifts per day | Capable of running 2-3 shifts per day | Capable of running 2-3 shifts per day | |

| Can do the following cuts | Bevel, Compound Miter, Crosscut, Dado, Miter, Rip (with Rip Kit Add On) | Bevel, Compound Miter, Crosscut, Dado, Miter, Rip (with Rip Kit Add On) | Bevel, Compound Miter, Crosscut, Dado, Miter, Rip (with Rip Kit Add On) | Bevel, Compound Miter, Crosscut, Dado, Miter, Rip (with Rip Kit Add On) | Bevel, Compound Miter, Crosscut, Miter | Bevel, Compound Miter, Crosscut, Miter | |

| Motor Phase | Single Phase, 3 Phase | Single Phase, 3 Phase | - | Single Phase, 3 Phase | - | - | |

| Phases of Voltage Available | 3 Phase, Single Phase | 3 Phase, Single Phase | 3 Phase | 3 Phase, Single Phase | 3 Phase | 3 Phase | |

| Motor | 3 HP 1 phase TEFC (totally enclosed fan cooled) motor, 3 HP 3 phase TEFC (totally enclosed fan cooled) motor | 3 HP 1 phase TEFC (totally enclosed fan cooled) motor, 5 HP 3 phase TEFC (totally enclosed fan cooled) motor | 5 HP 3 phase TEFC (totally enclosed fan cooled) motor | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor, 7.5 hp 3 phase TEFC (totally enclosed fan cooled) motor, VFD control with single phase input | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor, 7.5 hp 3 phase TEFC (totally enclosed fan cooled) motor, VFD control with single phase input | |

| Pneumatic Clamping Ability? | Yes (Add on) | Yes (Add on) | Yes (Add on) | Yes (Add on) | Yes (Add on) | Yes (Add on) | |

| Electronic Powered Cross Feed Option? | No | No | No | Yes (Add On) | Yes (Add On) | Yes (Add On) | |

| E-Stop | Yes | Yes | Yes | Yes | Yes | Yes | |

| Max Depth of Cut at 45 Deg Bevel | 1 3/4" deep | 2 1/2" deep | 3 1/4" deep | 3" deep | 3 1/4" deep | 4" deep | |

| Product Depth | 38" deep | 44 1/2" deep, 48" deep | 44 1/2" deep, 48" deep | 51" deep, 66" deep | 51" deep, 60" deep | 58" deep, 66" deep | |

| Max Out Rip | 30 1/4 | 28, 36 | 28, 36 | 40 3/4, 48 3/4 | - | - | |

| Max Miter at ¾” | 15" wide | 10 1/4" wide, 16" wide | 10 1/4" wide, 16" wide | 17" wide, 21 1/2" wide | 17" wide, 21 1/2" wide | 12 1/2" wide, 22" wide | |

| Table Height | 33" high | 33" high | 33" high | 34 3/4" high | 34 3/4" high | 36" high |

Original Saw Company’s Wood Cutting Radial Arm Saws set industrial-grade performance and reliability standards. Designed to deliver repeatable, consistent cuts, these saws last for generations, making them the ultimate investment for woodworking and industrial applications.

Renowned for their unparalleled power and precision, these Radial Arm Saws excel in various environments, including custom cabinet shops, school vocational programs, lumberyards, home centers, and manufacturing plants. Their versatility and durability are ideal for pre-fabricated housing, door production, truss plants, and crating departments.

Whether you’re a professional craftsman or an industrial operator, Original Saw Company’s Radial Arm Saws meet the demands of rigorous daily use, delivering dependable results for years.

Selecting the right Radial Arm Saw depends on several factors. Consider the following when making your decision:

For personalized recommendations, consult with the Original Saw Company team. We can guide you in selecting the best saw model, accessories, and configurations to suit your materials, cutting requirements, and operational demands.

Original Saw Company’s Wood Cutting Radial Arm Saws can make angled cuts such as bevels, miters, and compound miters. The saw carriage and the arm can tilt or rotate, allowing for precision in angled cutting applications. This feature makes it ideal for creating custom trim, molding, and furniture design angles.

The Contractor Duty Radial Arm Saws are designed for lighter workloads, making them an excellent choice for smaller shops, home hobbyists, or educational programs. With lower horsepower motors, these saws can crosscut over 21 inches and handle moderate woodworking tasks. They deliver dependable performance for less demanding environments and are perfect for those who need reliable cutting without industrial-level demands. Dado

The Heavy Duty Radial Arm Saws have more powerful motors and various cutting capacities, making them ideal for professional use in crating departments, lumberyards, and home centers like Home Depot. Designed for frequent use, they provide rugged reliability and are well-suited for demanding projects in busy professional and industrial settings.

The Super Duty Radial Arm Saws are built for continuous operation in high-demand industrial environments, capable of running during 2-3 shifts per day. Featuring the most powerful motors in the lineup, they deliver maximum crosscut and depth capacity, effortlessly handling large materials. Their industrial-grade construction ensures unmatched durability and consistent performance, making them the premier choice for production facilities and other intensive applications.

The VFD provides smoother start-ups and improved motor control by:

The VFD is standard on Super Duty models. Contractor Duty and Heavy Duty models can be upgraded to include VFD functionality.

Original Saw Company offers a variety of carbide-tipped blades for wood cutting to suit different applications:

Blades are sold separately and should be selected based on material and cutting needs.

Regular maintenance helps your Radial Arm Saw operate efficiently and reliably over time. Follow these guidelines:

Consistent maintenance helps extend the life of your saw and provides dependable, accurate cutting results.

Highlighting effective strategies from our clients.

TopShelf Wood Packaging manufactures wooden pallets, crates, boxes, dunnage, and other specialty wood shipping products.

Black Bros. Co. is a family-owned, sixth-generation roll coating and laminating equipment manufacturer established in 1882.

Charlie Kulisan, the owner of Kulisan Woodworking, is an advanced hobbyist woodworker. When searching for a replacement saw to handle crosscuts and dadoes, he prioritized safety and durability.

Original Saw Company offers a range of customization options to make your Radial Arm Saw perfectly suit your specific applications. From tailored electrical panels and specialized blade speed adjustments to optional accessories like Pneumatic Clamping and Saw Measuring Systems, configure Radial Arm Saws for optimal performance and precision.

Whether you’re handling odd-sized materials, requiring enhanced safety features, or seeking greater efficiency, our customizable solutions provide the flexibility and reliability professionals need.

Add extension tables for stable material support and measuring systems for precise, repeatable cuts, streamlining workflows for longer and larger materials.

Choose from MDF tops with T-slots, durable T-slot extruded metal tables, or HDPE inserts for smooth cutting. Add a bolt-on enclosed table guard with a dust port for safety and cleanliness.

Equip your saw with carbide-tipped blades, including general-purpose, fine crosscut, and dado blades, for versatility across wood, composites, and plastics.

Secure materials effortlessly with two- or four-cylinder pneumatic clamps, perfect for high-volume cutting, reducing fatigue, and maintaining precision.

Ask about sending in a material sample to Original Saw. We will cut your material on our shop saw and make a video. Afterwards, you can review the videoed test cuts and make informed decisions. Most importantly, we want you to feel comfortable with your solutions before your purchase.

Email us at customerservice@originalsaw.com or call at (800) 733-4063 to start the process.

Have questions or need assistance in selecting the right saw?

Our experts are here to help you choose the right equipment and systems for you.

Don’t miss out on valuable company updates from us!

"*" indicates required fields

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_N787K37DYQ | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_9586239_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| Cookie | Duration | Description |

|---|---|---|

| GetLocalTimeZone | session | No description |

| woocommerce_recently_viewed | session | Description unavailable. |

| wp_woocommerce_session_f5cd7dc109f1c0b99afb63cf04893d56 | 2 days | No description |

Select at least 2 products

to compare