Radial Arm Saws.

Beam Saws.

Crosscut Power Saws.

Original Saw Company is the industry leader in American made cutting equipment.

We manufacture Radial Arm Saws, Beam Saws, Crosscut Power Saws, Saw Extension Tables, Saw Measuring Systems and Miter Saw Stands.

Radial Arm Saws.

Beam Saws.

Crosscut Power Saws.

Original Saw Company is the industry leader in American made cutting equipment.

We manufacture Radial Arm Saws, Beam Saws, Crosscut Power Saws, Saw Extension Tables, Saw Measuring Systems and Miter Saw Stands.

Find a Distributor

Near You

Saw

Resources

DeWalt Radial Arm Saw

Replacement Parts

The Legacy of the Radial Arm Saw - From DeWalt to Original Saw and Beyond

Our company is rooted in history.

In 1990, Original Saw Company purchased the Radial Arm Saw product line previously owned by DeWalt and then Lancaster Machinery. As a company, we are proud to carry on the legacy of the renowned, American made Radial Arm Saw.

All of our industrial equipment is manufactured in the USA by our skilled employees that make up the Original Saw team. By using innovation in design and manufacturing, we create high-quality industrial equipment that simplifies cutting.

20″ Metal Cutting Radial Arm Saw

14″ Heavy Duty Radial Arm Saw

16″ Super Duty Radial Arm Saw

Saw Parts

Replacement parts are available for machines and accessories made by the Original Saw Company. We also carry several “wear” parts for older DeWalt saws dating back to the 1950s.

Since 1990

30 Years of American Made Products

Robert Eden had a vision of a company that would grow and build industry in northern Iowa. In 1976 Robert and his wife, Laurie, moved back to the area where they had grown up and settled in Britt, Iowa.

The late 80’s brought change for the family. As the tiling opportunities in the area dwindled, Robert and Laurie purchased Jones Machinery Company in Des Moines and moved the company to Britt in 1989. Jones Machinery Company serviced and sold parts for radial arm saws manufactured by Lancaster Machinery. Soon after, Lancaster Machinery was put up for sale. Realizing that Jones Machinery depended on the livelihood of Lancaster Machinery, Robert seized the opportunity to purchase the remaining inventory and rights to the business.

At that point, Original Saw Company was born.

The first radial arm saw was invented and patented in 1922 by Raymond DeWalt. When Lancaster Machinery purchase the rights to the radial arm saw, they coined the phrase “The Original” Radial Arm Saw. They wanted customers to know that the same standard and dependability of a radial arm saw would still be produced and it made sense for them to rename their new company Original Saw Company.

In the fall of 1990, Original Saw Company began in Britt, Iowa, with 11 models of radial arm saws ranging from 14” – 20” models and 5 employees. Today under Allen and Jennifer Eden (Second Generation) Original Saw Company continues to see growth in sales and product development.

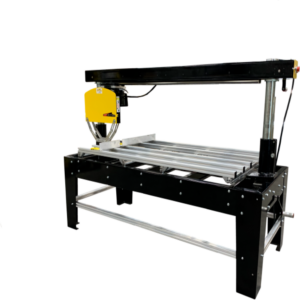

3600 Series Beam Saw In Action

This 3600 Series Horizontal Beam Saw (Model 3691-01-03) with optional power carriage will handle years of precision cutting. Simply push a button and watch the saw do all the hard work.

Blog

Check out our blog for updated Original Saw Company News and get “must know” tips on the latest saw technology.