Industrial Radial Arm Saw for Wood Packaging – TopShelf Wood Packaging

TopShelf Wood Packaging manufactures wooden pallets, crates, boxes, dunnage, and other specialty wood shipping products.

Need Help? 800-733-4063

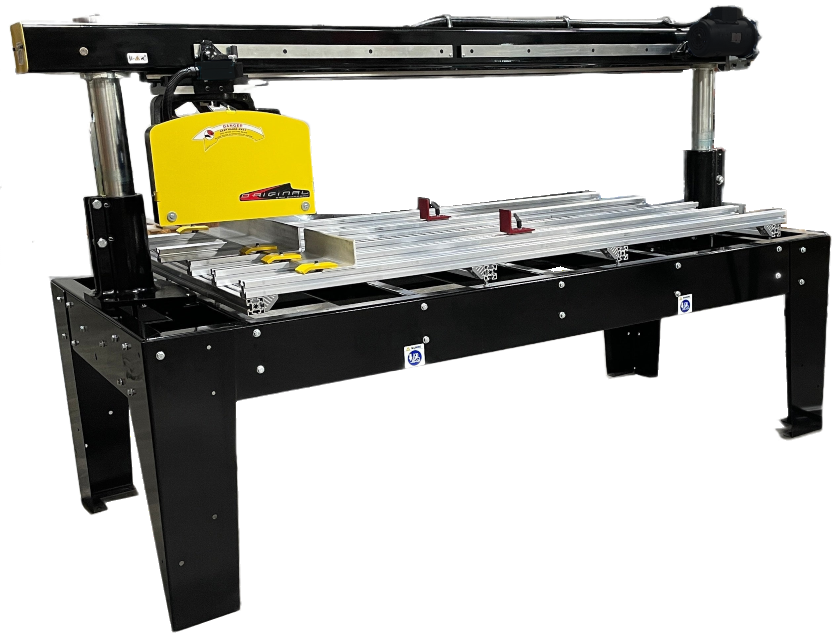

Original Saw Company’s Beam Saws deliver unmatched performance, durability, and versatility for industrial cutting applications. Manufactured in our Northern Iowa facility, these American-made machines are built from heavy-duty materials like cast iron, cast aluminum, and steel to ensure reliability and longevity.

Engineered for high-volume production, these saws easily handle demanding tasks like cutting wood, metal, aluminum, and composite materials. With a cutting capacity of up to 65 1/2″ long and 8″ deep, these saws excel in industries like panel production, curtain wall manufacturing, metal roofing, and steel construction.

Beam Saws are customizable with advanced features such as Electronic Powered Cross Feeds, Pneumatic Clamping Systems, and Mist Coolant Systems to maximize efficiency and precision. Whether in woodworking, metalworking, or construction, Beam Saws provide the reliability and accuracy professionals need to keep operations running smoothly.

Showing all 4 resultsSorted by price: high to low

Beam Saws from Original Saw Company combine industrial construction, advanced safety features, and precision engineering to deliver performance in demanding work environments. Designed for durability and reliability, these saws are built with heavy-duty materials and innovative technology, making them the ideal solution for high-volume cutting tasks.

From their rigid cast iron and aluminum construction to in-house-manufactured motors with Variable Frequency Drive (VFD) technology, Beam Saws provide consistent, vibration-free cutting. With features like T-slot extruded aluminum tables, custom electrical panels, comprehensive blade guarding, and accessible Emergency Stop (E-Stop) buttons, Beam Saws can handle a wide range of materials and applications safely and efficiently.

Beam Saws are engineered for durability and precision in industrial environments. They feature robust construction from cast iron, cast aluminum, box tubing beams, and powder-coated steel frames. Weighing 1,500 pounds, the saws provide a rigid and vibration-free cutting platform for consistent performance and reliability even in the most demanding industrial environments.

Original Saw Company builds custom electrical panels in-house to support the demanding performance requirements of our beam saws. By producing panels internally, we ensure electrical controls are purpose-built for our machinery, delivering consistent performance while maintaining close control over quality, cost, and lead time. Panels can be configured for a wide range of voltages, including those required for international applications.

Our standard panels offer reliable machine control and include key safety and performance features such as low-voltage operation, over-current thermal protection, and emergency stop (E-Stop) functionality.

For beam saw applications requiring additional flexibility, customized panel options are available. These may include hour meters to track arbor motor run time, keypad-style operator controls, and dedicated connection points to allow customers to interface their own RFID or access-control systems (customer-supplied). Internal panel construction also allows us to tailor blade speed controls to match different materials or larger blade configurations.

An onsite UL-listed panel shop allows certification to be provided when required. UL508A (United States) and CSA (Canada) certification is available upon request for customers with specific regulatory or export needs.

The Beam Saw comes standard with a T-slot extruded aluminum table, providing a stable, durable, and versatile work surface. Designed to support heavy-duty cutting operations, the table features manual clamps for secure material placement and an extruded aluminum fence for precise alignment.

The T-slot design allows for the easy attachment of additional clamping systems, alternate table surface options, and custom jigs or fixtures, enhancing flexibility and efficiency. Mounted on an extruded leveling frame, the table provides consistent, level support throughout the machine’s life.

Safety is a top priority with Beam Saws, which feature comprehensive upper and lower blade guarding for full coverage. These guards minimize operator risk by reducing exposure to the blade while still allowing clear visibility of the cutting area for precise operation.

The exclusive door-style guard makes for quick and easy blade changes. This convenient design is especially beneficial for high-volume or repetitive cutting tasks requiring frequent blade changes to maintain optimal performance. The door-style guard ensures that operators can safely and efficiently switch blades as needed, making it an essential safety component for demanding industrial applications.

An easily accessible Emergency Stop (E-Stop) button is an important safety feature on all Beam Saws. Designed for immediate response, the E-Stop allows operators to halt the machine’s operation instantly. This critical function minimizes the risk of accidents for a safer working environment, particularly in high-demand production settings.

Positioned for quick access, the E-Stop provides an added layer of control during operations where precision and safety are paramount. Whether addressing sudden material handling issues or unexpected blade movement, operators can safely intervene and make necessary adjustments before resuming work. The proper safety features offer peace of mind in busy industrial environments.

Original Saw Company’s Beam Saws are powered by industrial, in-house-manufactured TEFC (Totally Enclosed Fan-Cooled) motors. By making our motors onsite, we ensure exceptional quality and reliability. Designed for continuous use in demanding industrial environments, these motors are available in 5 HP single-phase or 7.5 HP three-phase configurations.

Integrated Variable Frequency Drive (VFD) technology provides high-performance operation by delivering smooth start-ups, precise blade speed adjustments, and reduced wear on components. The TEFC design protects the motor from dust and debris, minimizing maintenance needs and maximizing durability. These features provide efficient, reliable performance for various materials and cutting tasks.

Original Saw Company’s Beam Saws meet the rigorous demands of industrial environments, offering consistent performance and adaptability. All Beam Saws in the series share key features, including robust construction, the ability to bevel and crosscut, and compatibility with optional upgrades like pneumatic clamping and electronic-powered cross feed.

These machines can handle various materials, including aluminum, brass, bronze, copper, fiberglass, lead sheets, plastic, steel, and wood, making them an essential tool for diverse applications. Engineered to operate 2–3 shifts daily, Beam Saws are equipped with safety features like an Emergency Stop (E-Stop) and are proudly manufactured in the USA for superior quality and durability.

16" Beam Saw (single phase with 65 1/2" crosscut) |

16" Beam Saw (3 phase with 65 1/2" crosscut) |

20" Beam Saw (3 phase with 58" crosscut) |

22.5" Beam Saw (3 phase with 58" crosscut) |

||

| SKU | 3691-01-01-VFD | 3691-01-03-VFD | 3691-01-05-VFD | 3691-01-07-VFD | |

| Cuttable Material | Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel, Wood | Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel, Wood | Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel, Wood | Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel, Wood | |

| Max Crosscut | 65 1/2" wide | 65 1/2" wide | 58" wide | 58" wide | |

| Max Crosscut at Max Depth | 61 1/2" wide | 61 1/2" wide | 58" wide | 58" wide | |

| Max Depth Cut | 5" deep | 5" deep | 7" deep | 8" deep | |

| Max Depth of Cut at 45 Deg Bevel | 2" deep | 2" deep | 3 1/2" deep | 4" deep | |

| Can do the following cuts | Bevel, Crosscut | Bevel, Crosscut | Bevel, Crosscut | Bevel, Crosscut | |

| Capable of Rip Cuts | No | No | No | No | |

| Made in USA | Yes | Yes | Yes | Yes | |

| Recommended Usage | Capable of running 2-3 shifts per day | Capable of running 2-3 shifts per day | Capable of running 2-3 shifts per day | Capable of running 2-3 shifts per day | |

| Pneumatic Clamping Ability? | Yes (Add on) | Yes (Add on) | Yes (Add on) | Yes (Add on) | |

| Electronic Powered Cross Feed Option? | Yes (Add On) | Yes (Add On) | Yes (Add On) | Yes (Add On) | |

| Voltage Options | 208V, 230V | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | 208V, 230V, 460V, 575V | |

| Phases of Voltage Available | Single Phase | 3 Phase | 3 Phase | 3 Phase | |

| Motor | 7.5 hp 3 phase TEFC (totally enclosed fan cooled) motor, VFD control with single phase input | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor | 7.5 hp 3 phase TEFC (totally enclosed, fan cooled) motor | |

| Product Depth | 111" deep | 111" deep | 111" deep | 111" deep | |

| Product Height | 65" high | 65" high | 67" high | 69" high | |

| Product Width | 45" wide | 45" wide | 45" wide | 45" wide | |

| Price | $16,677.18 | $15,654.80 | $15,840.40 | $16,347.79 |

Engineered to handle demanding tasks, Beam Saws can make long 65 1/2″ crosscuts and process multiple materials simultaneously, including wood, aluminum, brass, steel, and plastics. With a robust motor and the option to add an Electronic Powered Cross Feed, these machines transform into semi-automatic workhorses, streamlining production.

Customizable features like a Pneumatic Clamping System further enhance precision and productivity. Built from cast iron, cast aluminum, and heavy-duty steel, Beam Saws provide vibration-free operation, making them an essential tool for industrial environments.

A Beam Saw is a heavy-duty industrial machine that makes long, straight crosscuts through thick materials like wood, metal, and plastics. Unlike a Radial Arm Saw, which is versatile for various cuts such as crosscuts, bevels, and rip cuts, the Beam Saw specializes in cutting large sheets, panels, and multiple stacked materials with precision and efficiency. Beam Saws are ideal for high-volume production environments that require large cutting capacities.

Beam Saws cut a broad range of materials with precision and efficiency, making them indispensable in various industries. These materials include:

With their strong construction, heavy-duty motors, and compatibility with specialized blades, Beam Saws deliver precise cuts across these diverse materials, meeting the demands of industrial production environments. Whether cutting single pieces or stacked materials, Beam Saws provide the power and reliability needed for various applications.

Beam Saws are vital in industries that demand precise, high-volume cutting for various materials. Their versatility and durability make them essential for the following applications:

Beam Saws excel in industrial environments when there are critical production demands. These machines are trusted across various industries for their ability to perform consistent, high-quality cuts.

While their primary function is performing long, straight crosscuts, their design allows for accurate bevel cuts when required.This cutting ability provides flexibility for various applications.

Additionally, customers can upgrade Beam Saws to perform dado cuts, further expanding their versatility. However, they cannot perform miter cuts, compound miter cuts, or rip cuts.

When selecting a Beam Saw, consider these factors:

For personalized recommendations, contact Original Saw Company’s customer support team.

Yes, Beam Saws from Original Saw Company offer a range of customization options to optimize performance and meet specific production needs:

These upgrades allow operators to customize their Beam Saw for improved productivity, precision, and versatility across various applications.

Beam Saws are designed with operator safety as a top priority and include the following features:

These safety features work together to create a secure cutting environment, even in demanding industrial applications.

The Electronic Powered Cross Feed allows operators to automate the cutting process. With this feature, the saw blade moves through the material at the push of a button on the control pedestal and automatically returns to its starting position. This upgrade is ideal for high-volume and repetitive cutting tasks, reducing operator fatigue and increasing efficiency.

Highlighting effective strategies from our clients.

TopShelf Wood Packaging manufactures wooden pallets, crates, boxes, dunnage, and other specialty wood shipping products.

Black Bros. Co. is a family-owned, sixth-generation roll coating and laminating equipment manufacturer established in 1882.

Leverette’s Construction has been in business for over 20 years. They specialize in general contracting and providing high-quality construction services to their customers.

Safety Speed, a leader in panel processing and fabricating equipment, needed an upgraded cutting solution for their packaging department.

Charlie Kulisan, the owner of Kulisan Woodworking, is an advanced hobbyist woodworker. When searching for a replacement saw to handle crosscuts and dadoes, he prioritized safety and durability.

Central Florida Lumber, a family-owned leader in commercial building materials, specializes in doors, hardware, and millwork. The company needed a more efficient method to cut custom doors for its steel door customers.

Original Saw Company offers a range of customization options to enhance the performance and versatility of your Beam Saw. Streamline operations with an Electronic Powered Cross Feed for semi-automatic cutting or add a Pneumatic Clamping System for secure, consistent material handling. Improve cut quality and extend blade life with a Mist Coolant System, which is ideal for non-ferrous metal cutting applications.

Enhance your workspace with Saw Extension Tables and Saw Measuring Systems for handling longer materials or HDPE Black Plastic Table Inserts for additional support when cutting smaller items. Choose from various saw blades designed for wood, ferrous, and non-ferrous materials to match your cutting needs.

These customization options allow you to tailor the Beam Saw to your specific industrial requirements for optimal performance and productivity.

Upgrade to semi-automatic operation with push-button control for smooth and efficient cutting. The blade automatically moves through the material and returns to the starting position, ideal for repetitive tasks.

Achieve secure and consistent material holding with a factory-installed Pneumatic Clamping System. This system applies even pressure, making it perfect for precision cuts and high-volume production tasks.

Use Saw Extension Tables to customize material handling operations in your workspace. Choose from flat or roller extension tables. Easily join tables together by connecting the tables with hardware.

Saw Measuring Systems provide quick and accurate measurements for cutting tasks. Customize the system to handle lengths from 4 to 32 feet. With a variety of sizes available, these systems fit seamlessly into your workspace.

Use a Dust Collection Kit to improve safety and manage cleanliness when cutting wood. It features a dust shroud with four 4″ dust ports. The kit mounts to the inside of the frame on the bottom edge of the table.

Beam Saw HDPE Black Plastic Table Insert Kits create a solid cutting surface. The inserts fit seamlessly into the table’s T-slot system and offer additional support for detailed cutting tasks.

Mist Coolant Systems improve blade life, reduce friction, and prevent overheating when cutting non-ferrous materials on Beam Saws. The Mist Coolant System is a three-part system that works with a siphon delivery system.

Select a saw blade that matches the material you are cutting with the Beam Saw. Original Saw Company offers a wide range of blades designed for wood, ferrous metals, and non-ferrous materials, ensuring optimal performance for various cutting applications.

Ask about sending in a material sample to Original Saw. We will cut your material on our shop saw and make a video. Afterwards, you can review the videoed test cuts and make informed decisions. Most importantly, we want you to feel comfortable with your solutions before your purchase.

Email us at customerservice@originalsaw.com or call at (800) 733-4063 to start the process.

If Saw Extension Tables are purchased at the same time as a saw, the tables will be shipped with the saw via freight truck. Lead time on saws with Saw Extension Tables is generally 3-4 weeks.

Saw Extension Tables can also be ordered without a saw. Tables are an in stock item and can be shipped out approximately 2-3 days after the order is placed.

They can be shipped by UPS or by freight truck, depending on the size and number of tables ordered. Contact Original Saw Company at (800) 733-4063 or customerservice@originalsaw.com for a freight quote.

Use the diagrams below to identify the type and year of your saw. This will help us find your needed part.

When determining the replacement parts needed for a radial arm saw, it is important to know the series and serial number of the saw. The serial number is located on a riveted tag on the front of the frame on a radial arm saw. Beginning in 1995, Original Saw Company assigned serial numbers by year, month, series and numerical.

A manual is sent with each radial arm saw. It provides important safety information, diagrams and instructions. Refer to the manual to determine the parts needed.

Can’t find your manual?

When determining the replacement parts needed for a beam saw, it is important to know the series and serial number of the saw. The serial number is located on a riveted tag on the front of the frame on a beam saw. Beginning in 1995, Original Saw Company assigned serial numbers by year, month, series and numerical.

A manual is sent with each radial arm saw. It provides important safety information, diagrams and instructions. Refer to the manual to determine the parts needed.

Can’t find your manual?

When determining the replacement parts needed for a Crosscut saw, it is important to know the series and serial number of the saw. The serial number is located on a riveted tag on the front of the frame on a crosscut arm saw. Beginning in 1995, Original Saw Company assigned serial numbers by year, month, series and numerical.

A manual is sent with each crosscut saw. It provides important safety information, diagrams and instructions. Refer to the manual to determine the parts needed.

Can’t find your manual?

Have questions or need assistance in selecting the right saw?

Our experts are here to help you choose the right equipment and systems for you.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_N787K37DYQ | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_9586239_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| Cookie | Duration | Description |

|---|---|---|

| GetLocalTimeZone | session | No description |

| woocommerce_recently_viewed | session | Description unavailable. |

| wp_woocommerce_session_f5cd7dc109f1c0b99afb63cf04893d56 | 2 days | No description |

Select at least 2 products

to compare